high quality 1 3 hp submersible sump pump with vertical supplier

Latest articles

One of the most frequently asked questions from our team of pump experts is: How do I pump slurry? With this in mind, our team of experts have provided a useful guide to pumping slurry.

high quality 1 3 hp submersible sump pump with vertical supplier...

high quality 1 3 hp submersible sump pump with vertical supplier 【high quality 1 3 hp submersible sump pump with vertical supplier】

Read More3. Both pumps and motors are designed separately.

high quality 1 3 hp submersible sump pump with vertical supplier...

high quality 1 3 hp submersible sump pump with vertical supplier 【high quality 1 3 hp submersible sump pump with vertical supplier】

Read MoreDredge Pump

high quality 1 3 hp submersible sump pump with vertical supplier...

high quality 1 3 hp submersible sump pump with vertical supplier 【high quality 1 3 hp submersible sump pump with vertical supplier】

Read MoreSelecting And Operating A Slurry Pump

high quality 1 3 hp submersible sump pump with vertical supplier...

high quality 1 3 hp submersible sump pump with vertical supplier 【high quality 1 3 hp submersible sump pump with vertical supplier】

Read MoreWhat is the best seal arrangement for the application?

high quality 1 3 hp submersible sump pump with vertical supplier...

high quality 1 3 hp submersible sump pump with vertical supplier 【high quality 1 3 hp submersible sump pump with vertical supplier】

Read MoreThe company uses advanced computer assistant engineering software to design products and technology, which makes our

high quality 1 3 hp submersible sump pump with vertical supplier...

high quality 1 3 hp submersible sump pump with vertical supplier 【high quality 1 3 hp submersible sump pump with vertical supplier】

Read MoreWZ series slurry pumps are developed on the wide adaption of both home and abroad advance technology and many years of slurry pump design and field operation experiences.

high quality 1 3 hp submersible sump pump with vertical supplier...

high quality 1 3 hp submersible sump pump with vertical supplier 【high quality 1 3 hp submersible sump pump with vertical supplier】

Read MoreA dredge pump contains a pump casing and an impeller. The impeller is mounted in the pump casing and connected to the drive motor via a gearbox and shaft. The front part of the pump casing is sealed with a suction cover and connected directly to the suction pipe of the dredger. The discharge port of the dredge pump is located near the top of the dredge pump and is connected to a separate discharge line.

high quality 1 3 hp submersible sump pump with vertical supplier...

high quality 1 3 hp submersible sump pump with vertical supplier 【high quality 1 3 hp submersible sump pump with vertical supplier】

Read MorePumps with replaceable parts and components can have an unlimited service life. A high quality customised slurry pump with replaceable parts can last you a lifetime and should therefore be considered as a very reliable long-term investment.

high quality 1 3 hp submersible sump pump with vertical supplier...

high quality 1 3 hp submersible sump pump with vertical supplier 【high quality 1 3 hp submersible sump pump with vertical supplier】

Read MoreSlurry Pump

high quality 1 3 hp submersible sump pump with vertical supplier...

high quality 1 3 hp submersible sump pump with vertical supplier 【high quality 1 3 hp submersible sump pump with vertical supplier】

Read More

Popular articles

- A slurry pump is a mechanical device used for the pressure-driven transfer of a fluid mixture (aka slurry). The fluid mixture consists largely of water as a liquid and solids as minerals, sand, gravel, human excrement, drilling mud or mostly crushed material.

- Dredge Pump

- In a word, the wear-resistant properties of the slurry pumps are stronger, and the ability to convey particles is also stronger. Generally, the capacity of the slurry pump is larger than the mud pump, which is mainly used for coal and metal ore washing. The mud pumps are more suitable for abrasive slurry is not very strong.

- It is often used if a short period of dry running is expected. Fluid is introduced into the area between the back of the seal face and the tight-fitting outlet on the drive side of the slurry pump.

- First, what is a slurry? A slurry is a semi-liquid mixture, usually consisting of fine particles. Examples of slurries can include manure, cement, starch, or coal suspended in water. There are countless other combinations that can be considered slurries. Because of the added particles and thicker consistency, special pump requirements should be considered. A standard pump may be able to handle the fluid, but not as effectively as a properly sized slurry pump.

- If you have experience pumping slurry, you know it is not an easy task. Slurries are heavy and difficult to pump. They can cause excessive wear on the pump and its components, and if they don't move fast enough, they can clog the suction and discharge lines. Most importantly, it can be a challenge to keep a slurry pump in use for a reasonable period of time. However, there are steps you can take to extend the life of your slurry pump and reduce the challenges of pumping slurry.

Latest articles

-

target=_blank title=Rubber Liner Pumps>Rubber liner pumps have been used for nearly a century to protect plants and equipment from wear and retain their place as the wear material of choice for pumping and separating fine-grained slurries.

-

As described below, there are several , types of pumps, that are suitable for pumping slurries. However, before considering which technology to use, we must address several key issues.

-

How Slurry Pumps Differ From Standard Pumps?

-

Dry Installation

-

Slurry Pump Impeller

-

As a pump supplier, Aier is specially engaged in the research of abrasion resistant materials of slurry pumps, sewage pumps and water pumps and the development of new products. The materials include high chrome white iron, duplex stainless steel, stainless steel, ductile iron, rubber, etc. If you want to get more information about >best slurry pump wholesale, welcome to >contact us today or request a quote.

overlock and coverstitch machine. They are essential for creating clean and professional finishes on a wide range of garments, from basic T-shirts and leggings to more complex garments like dresses and coats. These machines also allow for faster and more efficient sewing, as they can trim and finish edges in a single pass, eliminating the need for additional steps in the sewing process.

Leather hand stitching is more than just a method of construction—it's an art form that embodies tradition, skill, and a commitment to quality. As more people rediscover the value of handcrafted goods, the future of leather hand stitching looks promising. In a world that often prioritizes speed over substance, this timeless craft continues to captivate hearts, offering a refreshing reminder of the beauty of making things by hand. Whether as a hobby or a profession, leather hand stitching invites individuals to slow down and appreciate the craftsmanship behind every stitch, creating a lasting legacy one piece at a time.

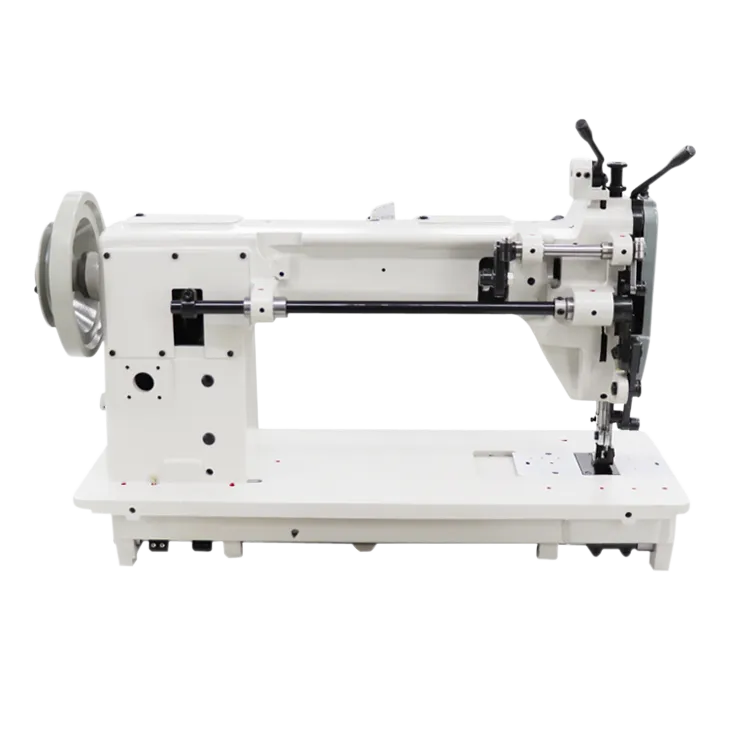

Investing in a compound feed heavy duty sewing machine can greatly enhance your sewing capabilities, enabling you to tackle a wide range of materials with ease and precision. As industries continue to seek efficiency and quality, these machines are poised to remain indispensable tools in the evolving landscape of sewing technology. Whether for personal projects or professional needs, a compound feed heavy duty sewing machine is a valuable addition to any sewing arsenal.

In addition to the precision it offers, the walking foot sewing machine also speeds up the sewing process. Since it minimizes the risk of fabric slippage and misalignment, less time is spent on corrections and adjustments. This efficiency translates to productivity, making it easier to complete large projects or multiple items in a shorter timeframe.

walking foot sewing machine

Conclusion

Moreover, these machines offer consistency in sealing quality. Every bag is sealed in a uniform manner, ensuring that the products are protected from environmental factors such as moisture, air, and contaminants. This consistency not only helps in maintaining product quality but also improves customer satisfaction by ensuring that each product meets the required standards.

automatic bag closer machine

Price

In industrial settings, these machines are celebrated for their efficiency. They can operate at high speeds, which significantly boosts productivity on assembly lines. The availability of various presser feet and attachments allows for specialized tasks such as zigzag stitching, blind hemming, and quilting.

single needle lockstitch machine

In summary, sewing machines designed for fabric and leather vary significantly in terms of functionality and specifications. To choose the right machine, consider the materials you'll be working with, the types of projects you plan to undertake, and the features necessary to handle various sewing tasks. Whether you're crafting intricate garments or durable leather goods, a well-chosen sewing machine will enhance your creativity and ensure your projects are completed with professional quality. Happy sewing!

Environmental Considerations

Applications in Sewing Projects

sewing zig zag machine

In the realm of industrial sewing, cylinder bed sewing machines have carved out their niche due to their unique design and versatility. These machines are particularly favored for sewing cylindrical or tubular items such as sleeves, cuffs, and pant legs. However, when considering the adoption of such equipment, potential buyers often find themselves wondering about the price range and what factors can influence these costs.

Sewing is an age-old craft that has undergone numerous innovations over the years. One of the most significant advancements in sewing technology is the zigzag sewing machine. Unlike traditional straight stitch machines, the zigzag sewing machine offers a variety of stitching options that enhance the creativity and functionality of sewing projects. This article explores the features, benefits, and diverse applications of the zigzag sewing machine.

At its core, a walking foot machine is designed with a unique feeding mechanism that allows the presser foot to walk along with the fabric as it moves through the machine. This mechanism is particularly beneficial when working with multiple layers of thick materials such as leather, canvas, or upholstery fabrics, which can be challenging to sew with standard sewing machines. The walking foot evenly feeds the layers of fabric through the machine, preventing slippage and ensuring that all layers move at the same pace. This results in a more consistent stitch quality and minimizes the risk of puckering or distortion.